Manufacturing Highlight: Fine Expression Silk Printing

Where durability meets aesthetics and cost-efficiency - that’s where Fine Expression Silk Printing (FESP) comes into play.

Posted Oct 20 '25

Where durability meets aesthetics and cost-efficiency - that’s where Fine Expression Silk Printing (FESP) comes into play.

Posted Oct 20 '25

We’re going to make a big statement here — in-mold labeling (IML) is the future of lighting design.

Posted Jun 11 '25

For having a notable impact on our everyday lives, in-mold labeling (IML) is a relatively unknown term for the general public. Also referred to as “film insert molding” or “in-mold decorating,” IML is the process by which a design becomes part of a plastic product.

Posted Feb 13 '25

Today, we celebrate 45 years of leading-edge production and entrepreneurial spirit that began with Mr. Tsutomu Goto's vision.

Posted Jul 25 '24

We use two highly-advanced technologies that provide a better solution for seamless parts: Hot-Cold Molding and CO2 Laser Cutting.

Posted Jun 24 '24

Two-shot injection molding allows for the seamless melding of two colors or resins. The materials are injected through independent nozzles, but into one plastic molding machine.

Posted May 22 '24

This year, our Malaysia factory is celebrating 30 years of producing top quality in-mold components and graphic overlays for manufacturers around the world.

Posted Mar 25 '24

Sputter coating is a commonly chosen method based on its high hardness, wear resistance, and cosmetic edge.

Posted Jan 17 '24

With over 40 employees, this factory supports many of our North American projects. From small batch orders to larger productions, Sanwa Mexico helps turn plastic-based visions into reality.

Posted Dec 20 '23

We’ve seen a high demand for futuristic designs that incorporate complex curves, 3-D effects, geometric patterns and metallic finishes.

Posted Nov 15 '23

At Sanwa Screen USA, we pride ourselves on offering high-quality In Mold Labeling (IML), Film Insert Molding (FIM), and In Mold Decorating (IMD) services for over 44 years.

Posted Oct 9 '23

We are proud to produce top-quality parts for Lexus, Subaru, Toyota and Ford, among others. So it was great to see some of our clients (and parts!) in action.

Posted Sep 25 '23

Since 1977, Sanwa has been a leading company worldwide in decorative techniques for applying screen printing and painting to molded materials. In 2014, we delivered another leading edge to customers with innovative solutions from a new factory in Zapopan, Mexico

Posted Jul 11 '23

When it’s time for your decorated plastic part to take shape, in-mold labeling (IML) can bring the worlds of 3-D form and creative design together.

Posted Jun 17 '22

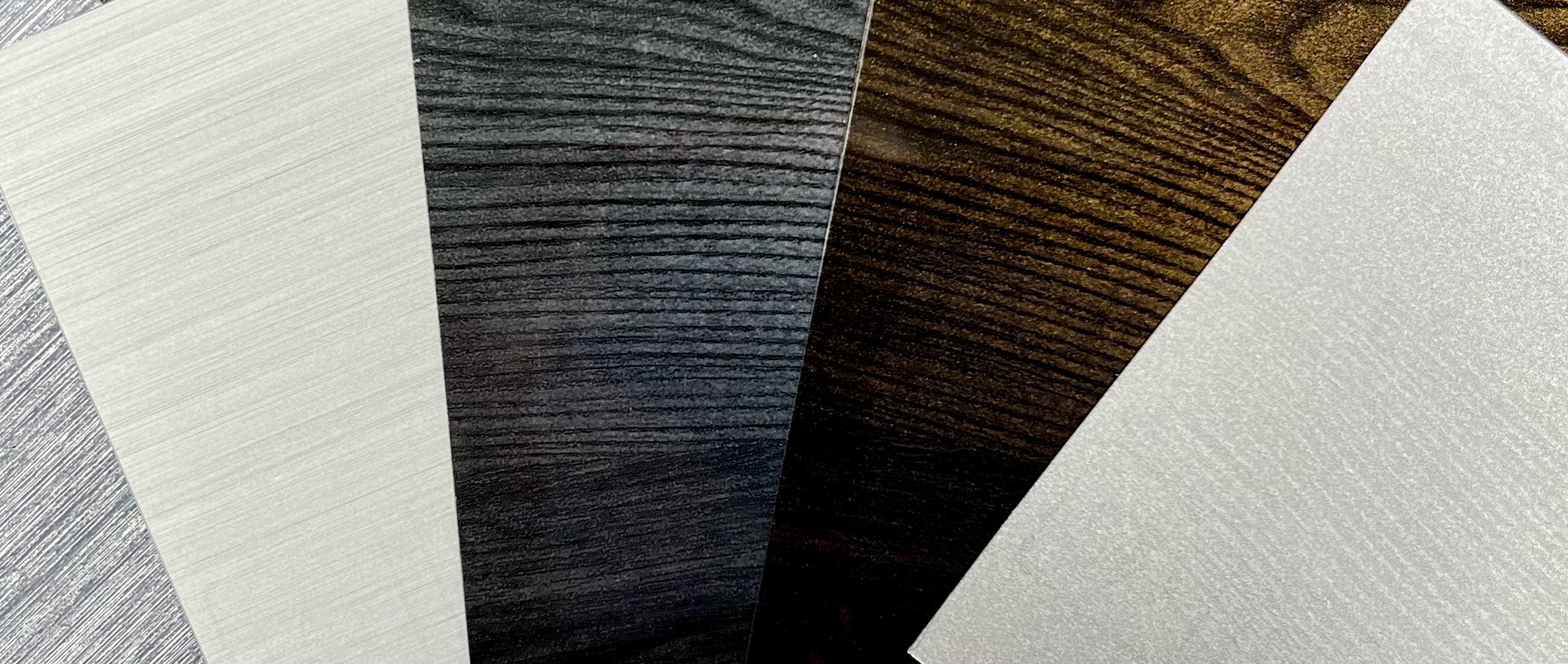

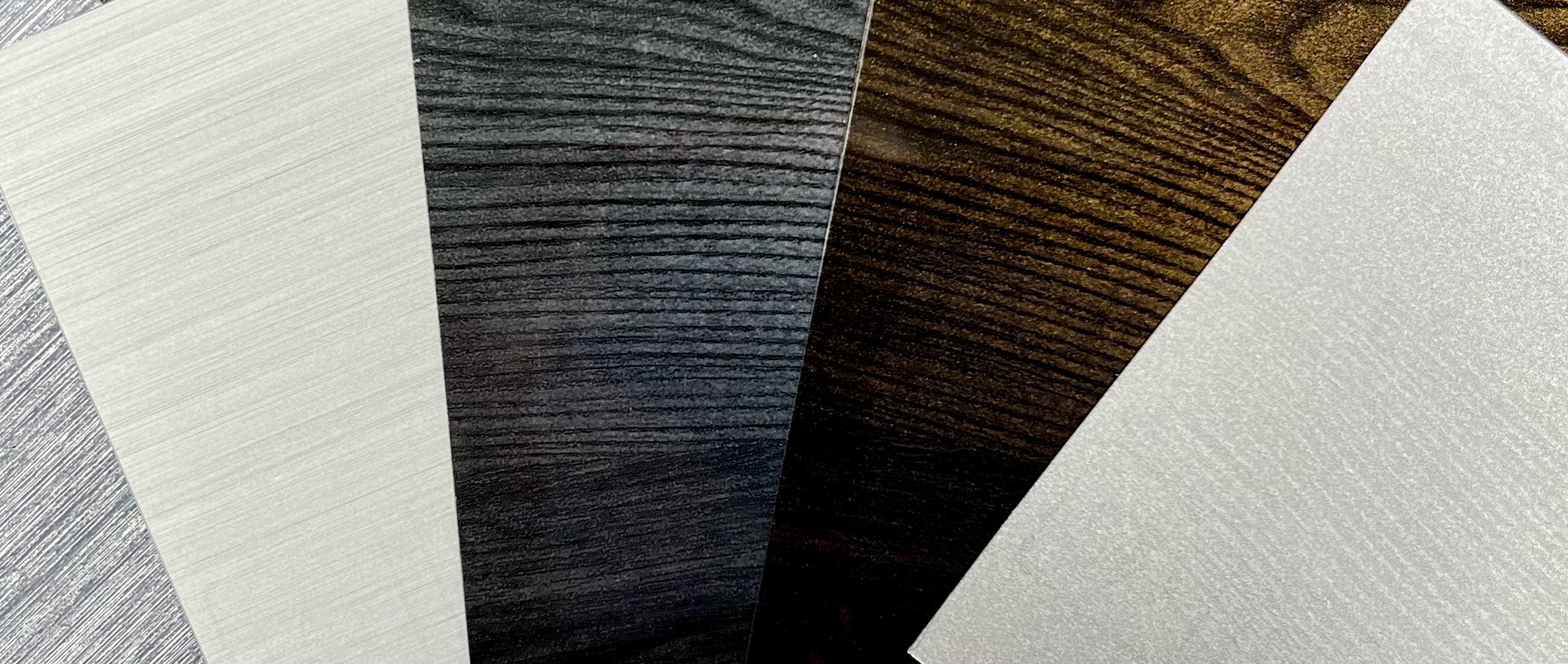

We’re able to mimic the look of rock, wood, and metal with in-mold labeling (IML), fine expression screen printing (FESP), and physical vapor deposition (PVD).

Posted May 20 '22

If you are interested in learning more about our transparent IML capabilities, or have questions about design or function, please contact us.

Posted Apr 20 '22

Manufacturing lines have faced shortages before, and our teams around the world are busy researching alternative materials to help ensure supply chains can continue moving smoothly.

Posted Mar 18 '22

![Article - What It Takes to Get Your IML Product Created [Timeline]](https://sanwascreenusa.us-east-1.linodeobjects.com/site_images/IML.001-Large.jpeg)

When it comes to in-mold labeling (IML), we can tell you how long each phase of production takes (on average), and what to expect at each step.

Posted Feb 21 '22

Before a Sanwa-produced IML part ever hits the shelf (or the product that it’s a part of — like a vehicle or washing machine) it goes through a series of tests.

Posted Jan 12 '22

Creativity, versatility, durability — in-mold labeling (IML) offers design freedom to give your plastic parts an outstanding aesthetic edge.

Posted Dec 15 '21