Sustainability at Sanwa: Our Commitment to Environmental Responsibility

April 25, 2025

At Sanwa, our teams around the world are passionate about responsible and sustainable manufacturing. Our commitment to reducing environmental impact and improving efficiencies isn't just good for the planet—it's smart business that benefits our employees, communities, and customers.

Efficiency in Design and Production

Our approach to sustainability begins in the planning stages. Our factory teams carefully calculate the most efficient layouts for printing projects, maximizing the number of items per sheet to minimize waste material. When multiplied across thousands of projects, these small efficiency gains translate to significant waste reduction and cost savings.

For molded parts, we work closely with customers to determine the most efficient designs. Our in-house tooling capabilities allow for rapid adjustments and quick communication, enabling on-the-fly production modifications that save materials and energy.

Advanced Coating Technologies

We offer PVD (physical vapor deposition) coating technology as an environmentally friendly alternative to chrome plating. Unlike chrome, which uses toxic chemicals such as hexavalent chromium, PVD is an eco-alternative that reduces chemical exposure. Our PVD process eliminates hazardous waste and VOC emissions while ensuring full recyclability of products due to the minimal metal layer thickness.

Water Conservation

Water is a precious resource essential to our manufacturing processes. Our factories have implemented internal water cleaning systems that allow for water reuse, significantly reducing our freshwater consumption. This closed-loop approach minimizes both water waste and the environmental impact of wastewater discharge.

Comprehensive Recycling Programs

In line with ISO 14001 requirements, Sanwa has established robust recycling programs across our facilities. Our approach includes:

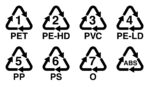

- Resin Recycling: We separate different types of plastic production excess and contract with specialized recycling companies that process these materials according to regulations

- Office Product Recycling: Paper, cardboard, and plastics are carefully separated and recycled at all locations.

- Food Waste Composting: Many of our factories feature cafeterias where food scraps are composted to create materials for future food production.

Upcycling Initiatives

Our commitment to resource conservation extends to creative upcycling. We transform leftover resin into golf tees, for example, and custom trays for holding and shipping products. This gives new life to materials that would otherwise be discarded.

Renewable Energy

Our Japan facility leads the way with solar panel installations that capture energy to power lighting, heating, and cooling systems. This renewable energy source significantly reduces our carbon footprint and dependence on conventional power sources.

Smart Energy Management

Across our facilities, we've implemented automated systems to conserve energy, including motion-sensor lighting and optimized temperature controls for heating and cooling systems. These small adjustments contribute to substantial energy savings over time.

Sustainable Packaging Solutions

Our teams expertly measure and arrange deliveries to maximize package space efficiency, which is particularly challenging with large, uniquely shaped custom parts. We utilize returnable packaging solutions, including reusable pallets and plastic totes instead of single-use wood and cardboard containers. Some of these pallets are shipped internationally between our warehouses and factories several times, extending their useful life.

Employee Engagement

Sustainability at Sanwa isn't just about corporate policies—it's a mindset embraced by our employees. We encourage My Cup, which is the use of personal reusable cups and water bottles instead of single-use containers, fostering a culture of waste reduction that extends beyond the workplace.

ISO 14001: A Global Standard

ISO 14001:2015 is an internationally recognized standard for environmental management systems. This framework guides our approach to designing, implementing, and continuously improving our environmental performance.

Our facilities in Japan, Malaysia, Thailand, Indonesia, and China have all achieved ISO 14001 compliance, with our Mexico facility set to receive approval by summer 2025. This global standard ensures consistent environmental practices across our international operations and demonstrates our commitment to sustainability at every location.

Quality as Sustainability

Perhaps the most fundamental element of our sustainability approach is our commitment to quality. When we produce high-quality parts that meet specifications the first time, we reduce the waste associated with defects and rework. This "get it right the first time" philosophy reduces material consumption, energy use, and ultimately keeps more products out of landfills.

At Sanwa, we believe that profitable business and sustainable operations aren't mutually exclusive—they're complementary goals that drive our innovation and success. We invite you to get in touch with our sales teams to learn about ways in which Sanwa can help you produce high-quality and long-lasting plastic parts mindfully and sustainably.