Unrivaled Quality. Faster Time-To-Market.

Sanwa produces superior in-mold decorated products and components so that you can drive competitive advantage.

The Complete Solution to All Your Parts Needs

Quality, service, innovation—our OEM products and components are produced entirely in-house making so that you can achieve consistent quality.

Dashboards, Control Panels, and Overlays

Reliable, high-quality decorated components and responsiveness to our customers’ specific requirements provide a critical competitive edge. Applications range from automotive to consumer electronics, appliances, medical and consumer products, and more.

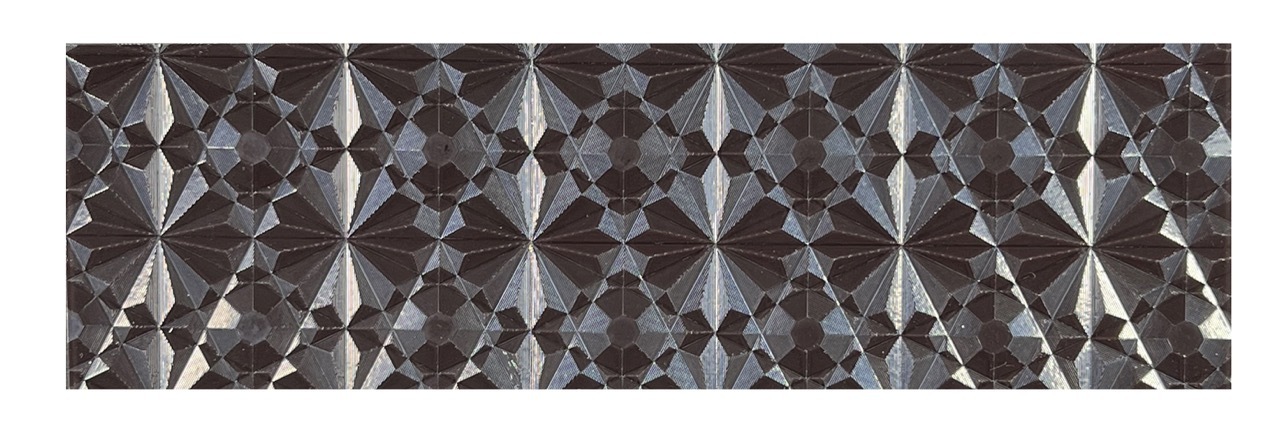

Decorative Trims and Injection Molded Parts

Sanwa's in-mold decoration (IMD) process produces fully-decorated parts with consistent quality. Our extensive capabilities from mold design and fabrication to mold maintenance and assembly make us the ideal one-stop manufacturer for your parts.Learn more about our OEM products and our consistent focus on quality and delivery.

Our Capabilities

Count on Sanwa to deliver the consistent service, innovative solutions and technical expertise you need to meet challenging supply chain deadlines, while focusing on total cycle time/cost performance.

See All Our Capabilities

Industries We Serve

Our experienced, knowledgeable staff partner with customers to provide innovative design/production, world-class quality and consistent delivery performance in a broad range of industries.

Appliance

Stylish, functional control panels for washing machines, microwave ovens, refrigerators, rice cookers and other appliances are consistently produced according to our customers’ quality standards. Utilizing our expert in-house design and production capabilities, we meet our clients’ deadlines for products that provide user-friendly control panel operation.

Why Sanwa

Sanwa supports customer goals for quality and total cycle time. Key elements in our customer-focused service include unmatched performance in design/engineering and quality, research and development, manufacturing, and our tuning, testing and prototyping capabilities.

Our Blog

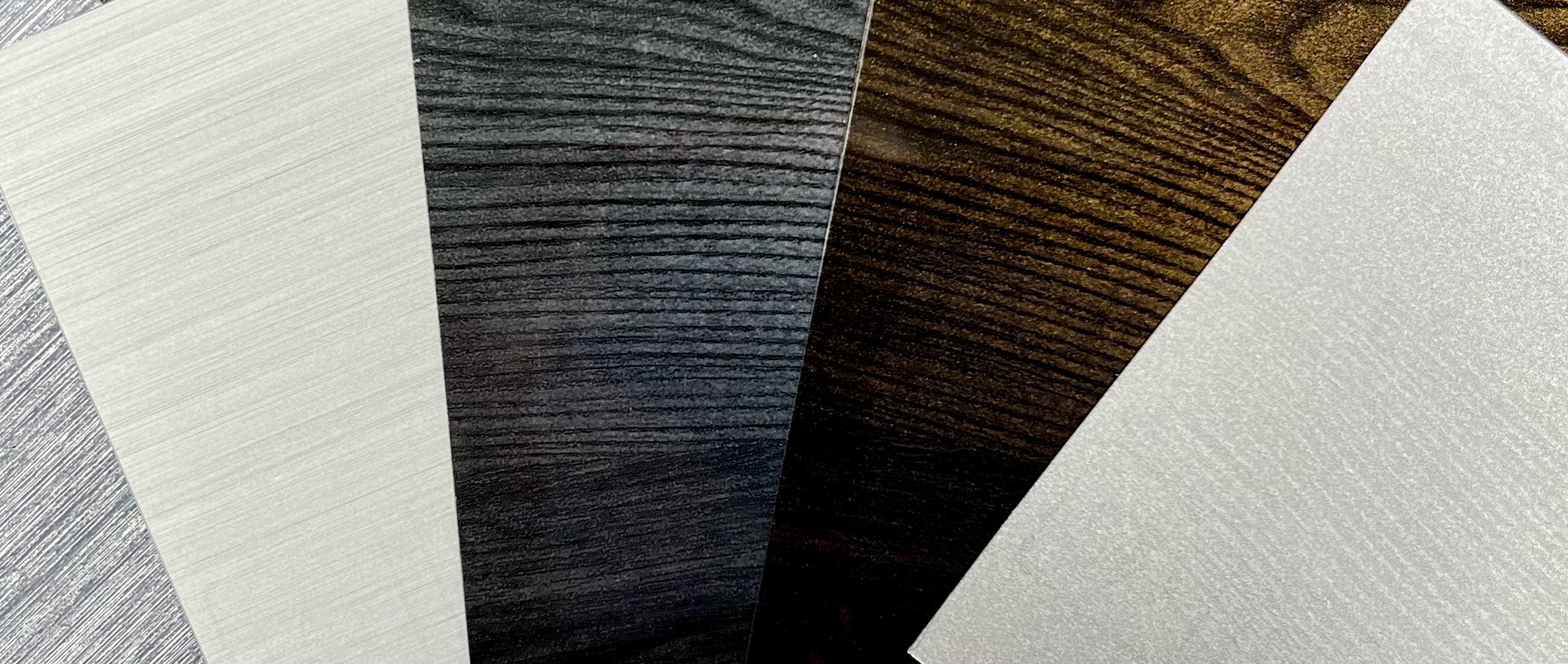

Sputtering and PVD Coating: Choosing The Best Method

Sputtering or physical vapor deposition (PVD) are used on decorative parts for their high hardness, wear resistance, and cosmetic edge.

Overlays: A Versatile, Cost-Effective Solution

Overlay technology has been around for decades, providing a reliable, economical way to create operation panels.

Manufacturing Highlight: Fine Expression Silk Printing

Where durability meets aesthetics and cost-efficiency - that’s where Fine Expression Silk Printing (FESP) comes into play.