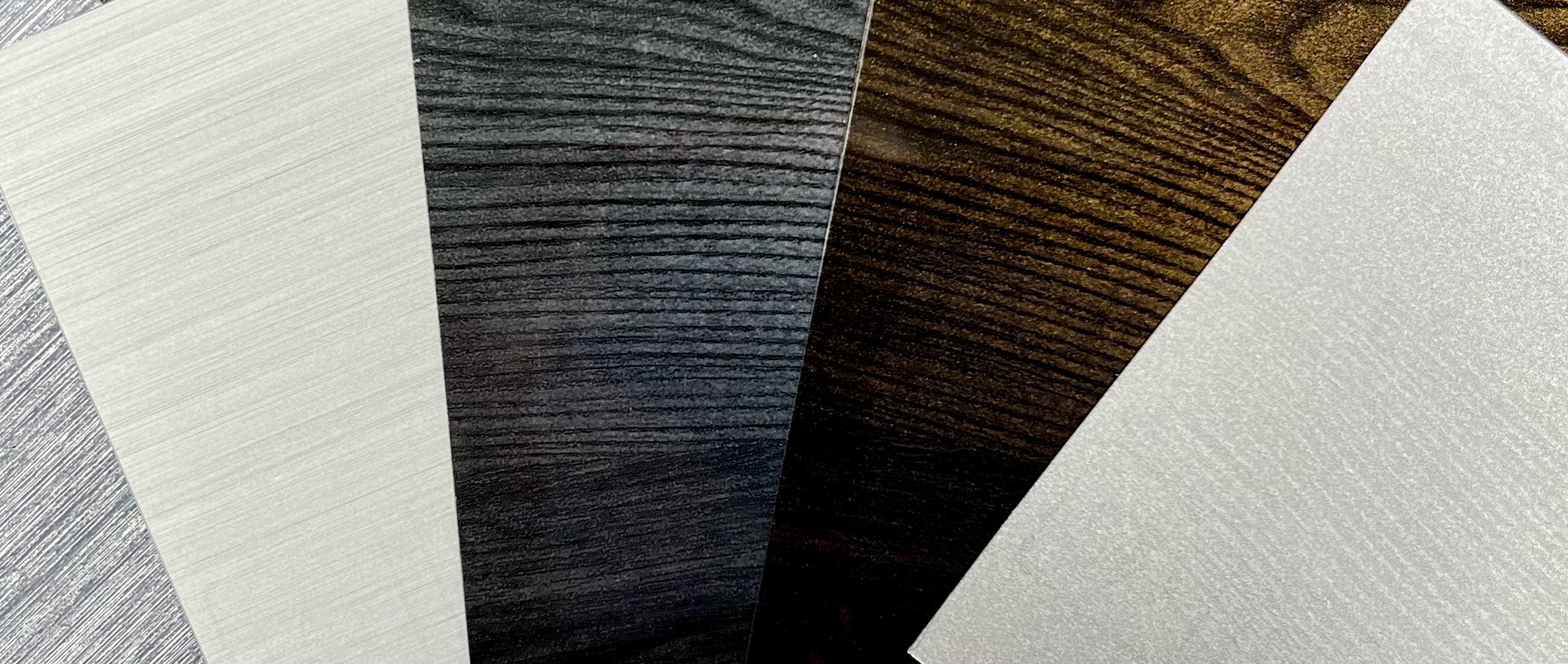

In-mold labeling—also known as in-mold decorating or in-mold graphics—is a process designed to outperform other post-production labeling alternatives.

By applying a label during the injection molding cycle, your design becomes a part of your product, rather than an adhesive or painted overlay.

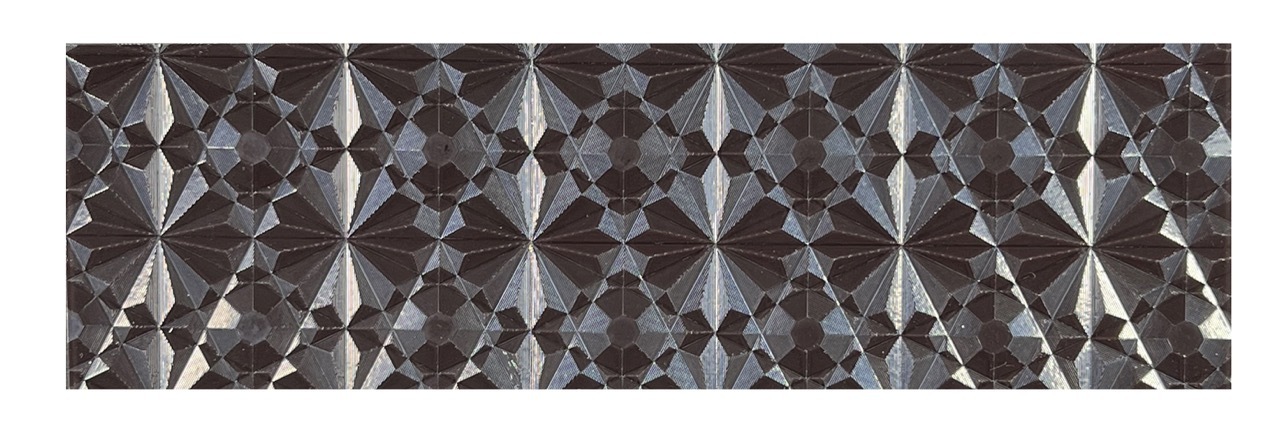

The result? High-end graphic effects that are made to last. In-mold labels diminish the occurrence of variations and defects, reduce waste, and can be used to give your product a high-end and aesthetic edge.