Sputtering and PVD Coating: Choosing The Best Method

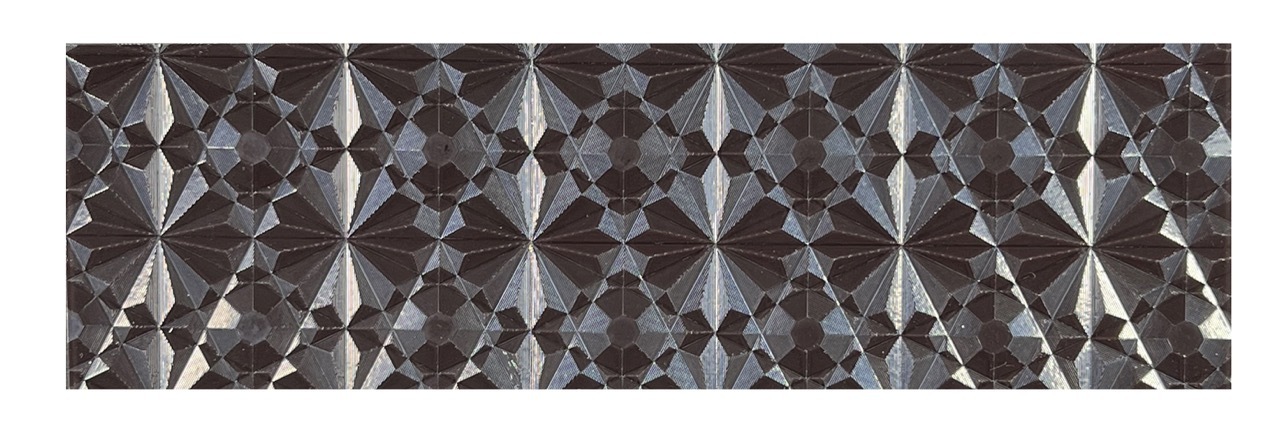

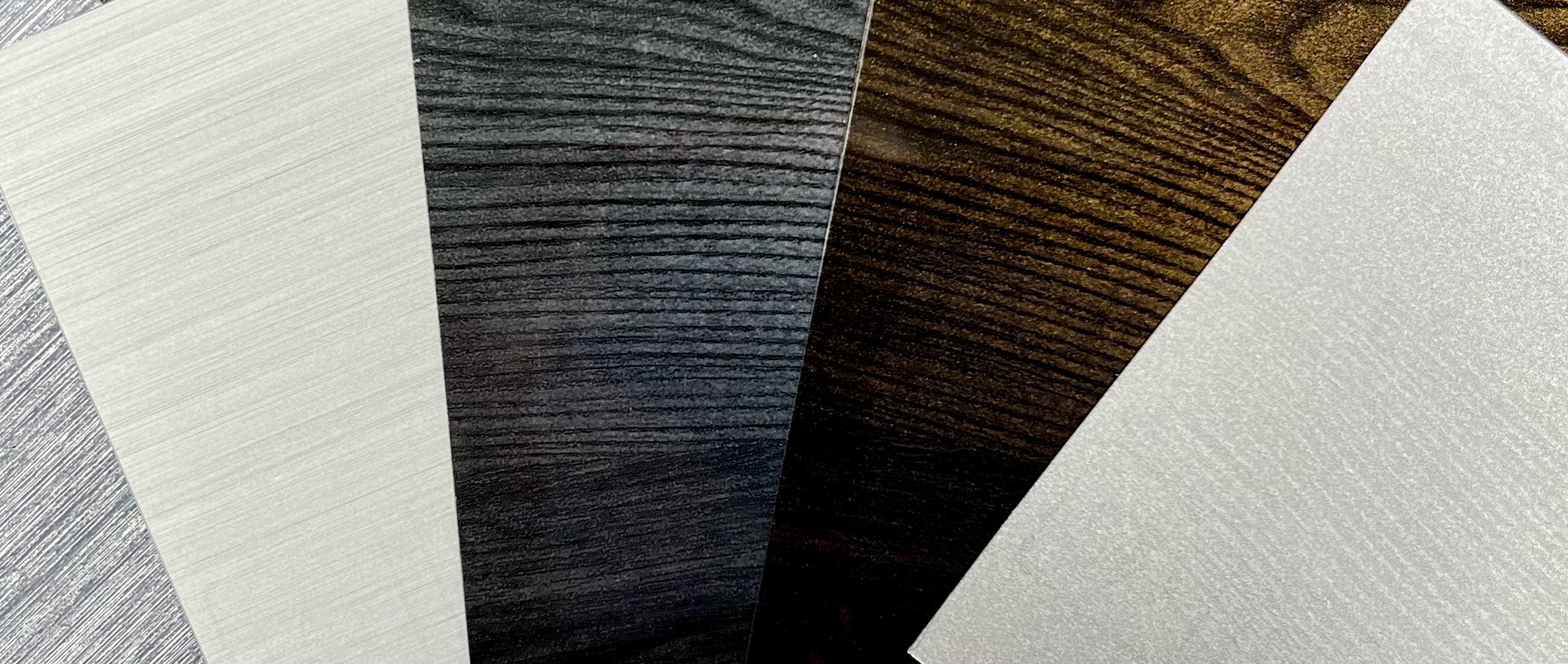

Sputtering or physical vapor deposition (PVD) are used on decorative parts for their high hardness, wear resistance, and cosmetic edge.

Posted Feb 10 '26

Stay up-to-date with information about In Mold Labeling and printing technologies, product and packaging design, frequently asked questions and more.

Sputtering or physical vapor deposition (PVD) are used on decorative parts for their high hardness, wear resistance, and cosmetic edge.

Posted Feb 10 '26

Overlay technology has been around for decades, providing a reliable, economical way to create operation panels.

Posted Jan 19 '26

Where durability meets aesthetics and cost-efficiency - that’s where Fine Expression Silk Printing (FESP) comes into play.

Posted Oct 20 '25

Operating agricultural and industrial equipment presents unique challenges for control interfaces. At Sanwa, we’re here to address those challenges with high performing in-mold labeling (IML) solutions that stand the test of time.

Posted Sep 22 '25

Sanwa has years of experience using dead front printing for a wide variety of products on the market. When you're ready to bring a backlit look to life, we can walk you through the possibilities.

Posted Aug 14 '25

At Sanwa, we're at the forefront of addressing visibility challenges through in-mold labeling solutions enhanced with anti-glare, anti-reflective, and anti-fingerprint coatings.

Posted Aug 4 '25

We’re going to make a big statement here — in-mold labeling (IML) is the future of lighting design.

Posted Jun 11 '25

When Sanwa Screen Printing Company first began in 1979, the vision was to grow a people-first company. More than four decades later, we've become a global organization with over 1,600 employees worldwide.

Posted May 19 '25

At Sanwa, our teams around the world are passionate about responsible and sustainable manufacturing.

Posted Apr 25 '25

A brand —and specifically a logo—plays a crucial role in the lasting impression. This is where in-mold labeling comes into play.

Posted Mar 24 '25

For having a notable impact on our everyday lives, in-mold labeling (IML) is a relatively unknown term for the general public. Also referred to as “film insert molding” or “in-mold decorating,” IML is the process by which a design becomes part of a plastic product.

Posted Feb 13 '25

Think about the last time you were on an airplane. What did you see and touch? Chances are that you interacted with parts that are excellent candidates for in-mold labeling.

Posted Jan 8 '25